Repair PCB Flex Circuits

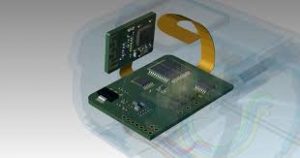

PCB flex circuits are hybrid types of printed circuit boards that incorporate flexible layers interconnected with rigid sections. These flexible circuits can offer a combination of flexibility and stability that is ideal for many applications. While these circuits can provide a variety of benefits, they can also be vulnerable to damage and wear over time. In order to ensure that these circuits perform as expected, it is important to know how to repair them if damaged. Here are a few methods to consider.

1) Repairing a broken wire: This is the most common type of damage to a pcb flex that can be repaired. It may be caused by external pressure or mechanical stress on the board that causes the trace to break and interrupts the electrical pathway. In most cases, this can be fixed by resoldering the broken section of the trace. 2) Re-establishing a conductive path: This can be done by using conductive paint or adhesive-backed copper tape. Once these materials are applied to the traces, they can be heated with a soldering iron to melt and bond them together. This method is effective for repairing damaged circuits and restoring their functionality.

3) Repairing a faulty or broken component: This can be done by identifying the specific components that need to be replaced and then ensuring that compatible replacements are available. This can be a relatively simple process, but it is important to ensure that the replacements are compatible with the existing design of the flex circuit. In some cases, this can require the removal of the existing component and then reseating it in a new position on the flex circuit.

How to Repair PCB Flex Circuits

Rigid-flex circuits have a unique set of challenges that can make them difficult to repair. These circuits are prone to a variety of different types of damage, including ripped and cut flex material, heat-damaged/lifted pads, and damaged conductors. Many of these issues can be resolved by repairing or replacing the affected parts of the circuit, and re-establishing a functional connection.

The most common base raw material for a flex circuit is polyimide, which is a tough and durable plastic that can be flexed over a range of angles without losing its shape. It is also highly tolerant to repeated solder reflow cycles and to temperature fluctuations, making it an excellent choice for use in a flex circuit. It is also very resistant to radiation and chemical exposure, which can be a benefit in some applications.

Other common substrates for flex circuits include PI and PET films, as well as glass fiber and epoxy. All of these materials are used to cover a conductive layer that is printed with circuit patterns. These layers are then etched and plated to create the desired wiring pattern. Rigid-flex circuits also often utilize stiffeners, which are rigid materials that are added to selected areas of the board in order to provide additional structural support. These stiffeners can be made from a variety of materials, but are typically created from FR4 or metal (not mentioned what kind). These stiffeners help to provide the extra structural support that is needed to support the flex circuit’s unique layout and design.